Having the proper fishing gear—a high-quality fishing rod—is as essential in fishing sport as in any other sport. Quality fishing rods can help make or break an angler’s chance of success out on the waters. The correct fishing rod for the situation will help an angler cast accurately, work the lures and baits to attract fish, detect bites and set the hook to land a fish.

Here at Seahawk, we are set on a mission to create exclusive high-quality fishing rods that are consistent and durable, yet come at an accessible price point. We believe you do not have to sacrifice quality and performance when pricing is reduced. In short, we create fishing rods that are tough on fish, but easy on the wallet.

For high quality and reliable fishing rods that last a long time, detailed attention is required across all levels of the fishing rod production process to ensure consistency and excellence. As such, we take the fishing rod creation stage seriously; from blank construction to thread-wrapping, right down to component selection and fitting to ensure the highest consistency and quality in the finished product.

Find out how our exclusive fishing rods are made through an overview of our Seahawk rod production below!

In creating a rod blank, a sheet of material called a prepreg is used. We hand-select the best carbon fibre prepreg to be cut according to specific attributes determined by us. These attributes include overall length, action, weight, line class & lure weigh class. A scrim could be added to the prepreg to increase action and strength.

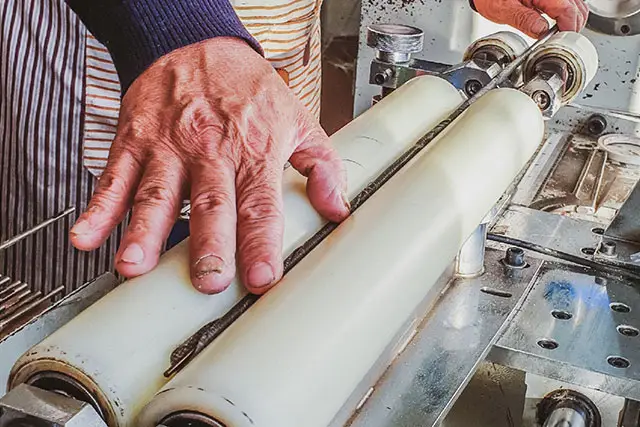

Once the prepreg has been cut into the specified shape and scrim is applied, it will be pre-painted with resin, a modified epoxy. The sheet(s) will then be rolled around a mandrel using a high amount of pressure from a rolling machine. This process squeezes out excess epoxy and minimises faulty weaknesses.

A molding tape called a cellophane exterior is applied to the surface to keep everything together during the baking process. The materials are then placed in an oven to be cured and hardened.

After the baking process, the rods are removed from the mandrels and then cooled. The ends are trimmed then polished on a grinding wheel to prepare the surface for painting. The completed blanks are then ready to be inspected and carefully selected for consistency and evenness.

The batch of fishing rod blanks will go through the finishing process of polishing and painting. Rods assigned to be fitted with guides will be placed on a rotating thread wrapping machine. The machine is controlled by a foot pedal and the rods are threaded one by one. This particular job requires great skill and experience.

During assembly, pre-selected high-quality components are added to the blanks. These items include the butt-cap or gimbal, lower handle material, reel seat, upper handle material, guides, and rod tip.

A flamed finish technique is applied to heat and remove bubbles. The guide bindings will be coated multiple times using a 2-component epoxy resin. During this process, proper care is taken to keep the overlay thin to eliminate distortion by the centrifugal force. The fishing rod is then placed in a drying furnace for a day.

After curing, the epoxy has fully hardened to keep the rod safe and secure from outside influence. Each fishing rod is then inspected for its appearance, quality, and workmanship. Minor adjustments will be done during this process. The finished rods are then carefully packed, ready to be distributed locally and globally.

You can also browse fishing rod products from our main site.