The main purpose of a fishing lure is, first and foremost, to attract and catch the attention of predatory fish. Its ultimate aim; to trick these predatory fish into biting the lure and hook. It does this by resembling fleeing or wounded fish through specific movements, vibrations, and colours. Aside from looks, it also has to be tough and durable enough to withstand constant fish attacks, trip after trip.

Fishing lures come in many different shapes, sizes, colours, and styles. They are crafted and designed differently as many factors come into play in the creation of a fishing lure.

The development of the best fishing lures is based on factors such as target fish species, time of day such as for day fishing or night fishing, target depth, castability, seasons, cover and structure and even specifically for the clarity of water, whether clear or murky. Some even come with additional attractants like fish scents and noisemakers to draw fish to the area.

At Seahawk, our aim is to bring all these factors into consideration, maximise on them, and combine these factors into the exclusive creation of our Seahawk fishing lures that ultimately deliver and produce consistent results, while also producing highly durable lures that can see anglers through plenty of fishing trips.

In order to produce consistently high-quality products that have been proven in the field, Seahawk exclusive fishing lures involve hand-crafting and manual assembly, even for mass production.

Find out how our exclusive fishing lures are made in an overview of our lure creation process below!

In the beginning, a sketch is made according to design specifications. Based on the sketch, an ABS model is carved out. From there, an exact ballast is inserted and weighed.

The prototype of the fishing lure will undergo an action test to determine the effect of the ballast on the action of the lure. Then, the 1st injection bodies are created and inspected for immaculate consistency. The ballast, hook positioning and lip angle have to be in perfect tolerance of one another.

Upon completion of the action test, the prototype is then digitally scanned and machine cut to create ultra-precise duplicates. The replicas will then undergo assembly. Internal componentry such as alloy balls, reflection plates will be inserted.

Once assembled, the body halves will be welded together using an advanced process involving high frequency acoustic vibrations. The workpieces are held together under pressure in order to create a solid-state weld. This cutting-edge process does not involve connective bolts, nails, soldering materials or adhesives.

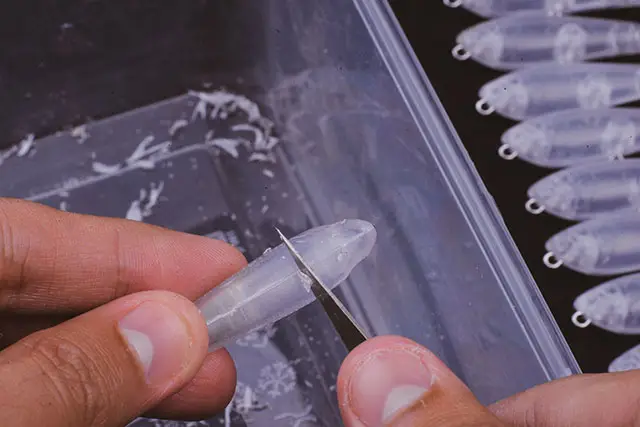

The welding process creates excess in the welds called burrs. To eliminate them, the lures will undergo precision deburring and edge finishing to transform the fishing lures’ rough matte edges into a smooth surface. This also helps prepare the surface to better adhere to paint for the painting process.

Painting is done manually by hand, one careful layer at a time. The fishing lure will be coated in multiple layers of paint in the exact selected hues. Then, numerous applications of measured clear UV top coat is applied on top to protect the paint below.

After painting, the fishing lure body will be inspected for paint integrity. The approved models will then be carefully attached with realistic three-dimensional eyes and premium hooks by hand.

The finished product will be randomly selected to undergo numerous tests including water immersion, tank tests, rapid casting, and field tests.

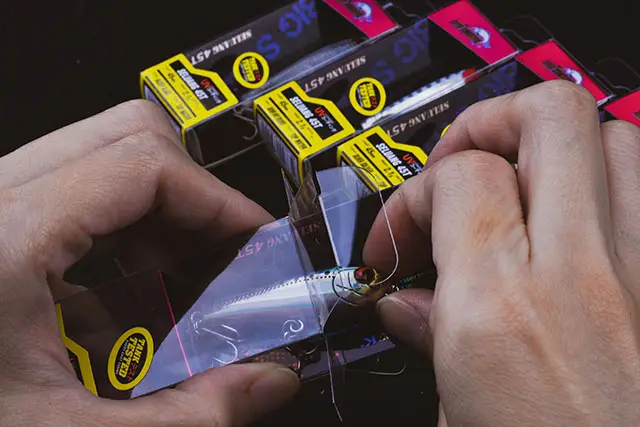

Once the fishing lures have passed the tank test, they will go through one final quality control inspection. Approved lures will then be packaged and be ready for distribution.

You can find out our team seahawk and seahawk fishing lures on our main website too.