The fishing reel is a sleek and beautiful yet complex piece of machinery.

Many different parts come together to form one unified body made to operate flawlessly in order to provide a smooth experience, and also to take constant abuse without falling apart. This ensures a solidly built and reliable fishing reel that can withstand thrashes during vicious fights with fish and last a long time.

This precise consolidation requires searing focus and attention to detail right from the beginning, which is the creation of the fishing reel’s various parts; highly detailed gears, sections, and tiny delicate components. As even the tiniest asymmetry in parts can render a fishing reel completely inoperative or unusable.

At Seahawk, we are committed to the exclusive creation of high-quality craftsmanship to ensure a consistent superior finished product. As such, we understand the utmost importance of maintaining thorough attention to detail throughout our entire fishing reel production process, especially in keeping a diligent eye in the early stages of gear processing and parts manufacturing before assembly. All completed parts should easily fit together but be tough to come apart.

Fishing reels come in a variety of shapes and sizes. Seahawk fishing reels consist of the traditional reliable spinning reels, and the more advanced and powerful baitcasting reels. Whichever the type of fishing reel, we maintain detailed scrutiny across all levels of our exclusive reel production.

From the early stages of beginning fishing reel ideation to our final product quality check and inspection before mass production, our aim at Seahawk is to create immensely capable high-quality fishing reels that are highly durable to see anglers through countless fishing trips and last a long time.

Find out how our exclusive Seahawk fishing reels are made with an overview of the production process featuring one of our spinning reels below! We also have a large range of the collection available for browsing at tce-sports.

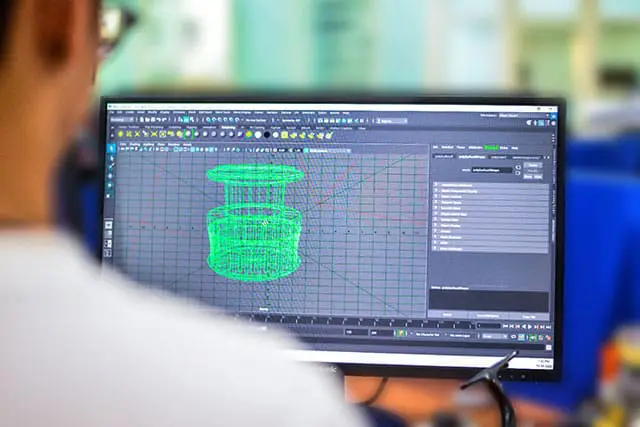

At the start, designers come together to draft and design the fishing reel using ideas derived from decades of research and customer feedback to form a prototype. Then, exact moulds are made according to the drafts of the design.

A series of computer-guided machines utilizing automatic CNC are used. This enhances high precision gear production to process gears and parts with delicate and refined features. Separate machines are used to carve out the reel’s frame and inner parts; each dedicated solely to carving out highly detailed parts such as spindle, pinion gears and main gears.

Often times during this process, anodizing is included. Selected parts are dipped in a series of chemical baths to increase thickness of the natural oxide layer on their metal surface.

After all machined parts are completed, the fishing reel body will undergo various finishing processes involving painting using multiple layers of coating or printing, then tumbling, polishing etc.

After the finishing process, it is time for the reel assembly. All machined parts will be manually inspected and carefully selected. Parts with the highest symmetry are selected to ensure the most secure fit for the smoothest rotation. These are then assembled by hand. Workers first install the inner parts of the reel. The spindle is fitted with bearing, sturdy washer, drag plate, click plate, and pinion gears before being inserted into the frame. Here, the reel will also be subjected to abrasion and quality strength tests.

Once assembly is completed, the reel will go through a complete manual inspection. Workers will test the drag level and gears to check if they engage properly. The reel will then be further subjected to high and low temperature tests, life tests, and delivery simulation tests to ensure it can be used under all conditions. The approved prototype will then undergo precise mass duplication before being packed for distribution.